Labeling solutions for bottles and cylindrical objects

1-2 of 2

Afinia A200 Bottle Label Applicator

| SKU | AFI-A200 |

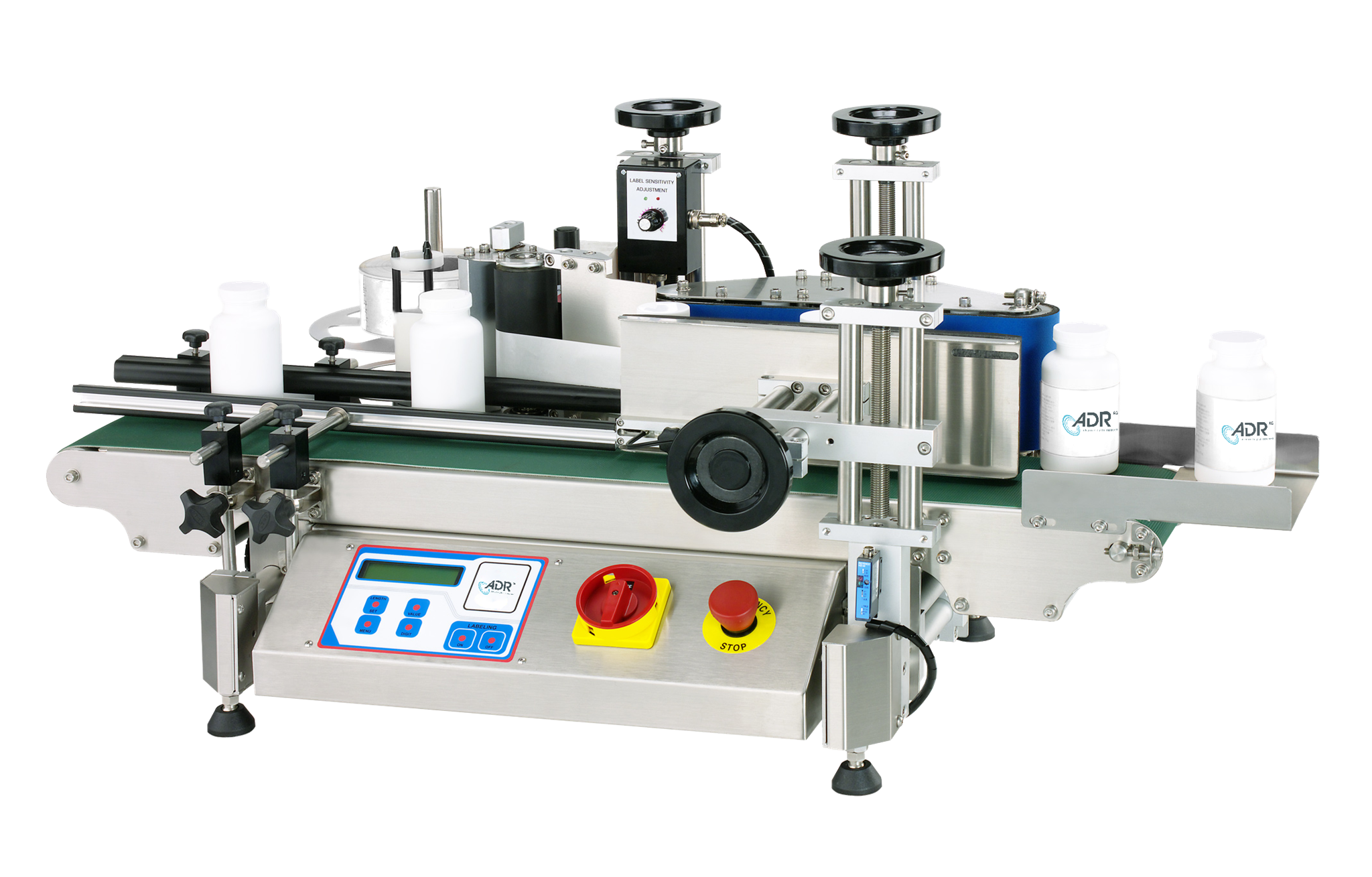

LAB8050 Labeler for cylindrical containers

| SKU | VMLAB8050 |

The Best Labeling Machines for Bottles and Efficient Labeling

What Are Bottle Labeling Machines?

Bottle

labeling machines are specialized devices designed to automatically and

accurately apply labels to bottles, cans, and jars. They are used

across various industries such as beverages, food, cosmetics, and

pharmaceuticals, ensuring consistent and professional product labeling.

The information required by law on labels plays a crucial role in

consumer information and sales success.

Whether

for wine bottles, beer bottles, cans, or other items, these machines

offer a reliable solution for comprehensive labeling. With a range of

features and models, they enable businesses to label their products

efficiently and to a high standard. Labels not only enhance visual

appeal but also fulfill legal requirements b including ingredients,

manufacturing dates, and expiration information.

Looking

to upgrade your production with a top-tier bottle labeler? Explore our

extensive range of labeling machines to find the perfect solution for

your needs. Contact us for more information and personalized advice.

Start today and present your products flawlessly!

Features and Benefits of Bottle Labeling Machines

Labeling

bottles, also known as bottle labeling, is crucial in industries like

wine, beer, and pharmaceuticals. A comprehensive labeling machine

efficiently and quickly label cylindrical products such as bottles,

cans, and jars.

These

labeling machines allow for rapid and precise label application,

leading to increased efficiency and productivity in production lines.

Compared to manual labeling, they offer significant advantages,

including consistent label placement on various bottle sizes and shapes,

reduced errors, and the ability to handle large volumes of products

quickly.

Types of Bottle Labeling Machines

There are several types of bottle labeling machines, each suited to different needs and applications:

Manual Labeling Machines:

Manual labeling machines are a flexible solution for smaller production runs and handcrafted products. They allow for precise and individual label application, as handling is directly performed by the operator.

These

machines are particularly useful for businesses that need to use

various label sizes and formats without investing in complex automated

systems. They are easy to operate and require minimal training. For

example, the LAB01 labeler is ideal for small batches of bottles, cans, jars, and other cylindrical objects.

Semi-Automatic Labeling Machines:

These machines require some manual intervention but offer greater efficiency and accuracy compared to fully manual methods. They are a cost-effective solution for smaller operations or production lines with moderate volumes.

Semi-automatic

label applicators are typically operated by a button or pedal to

activate the labeling process. ADR AG also offers solutions with integrated printers for adding expiration dates or serial numbers.

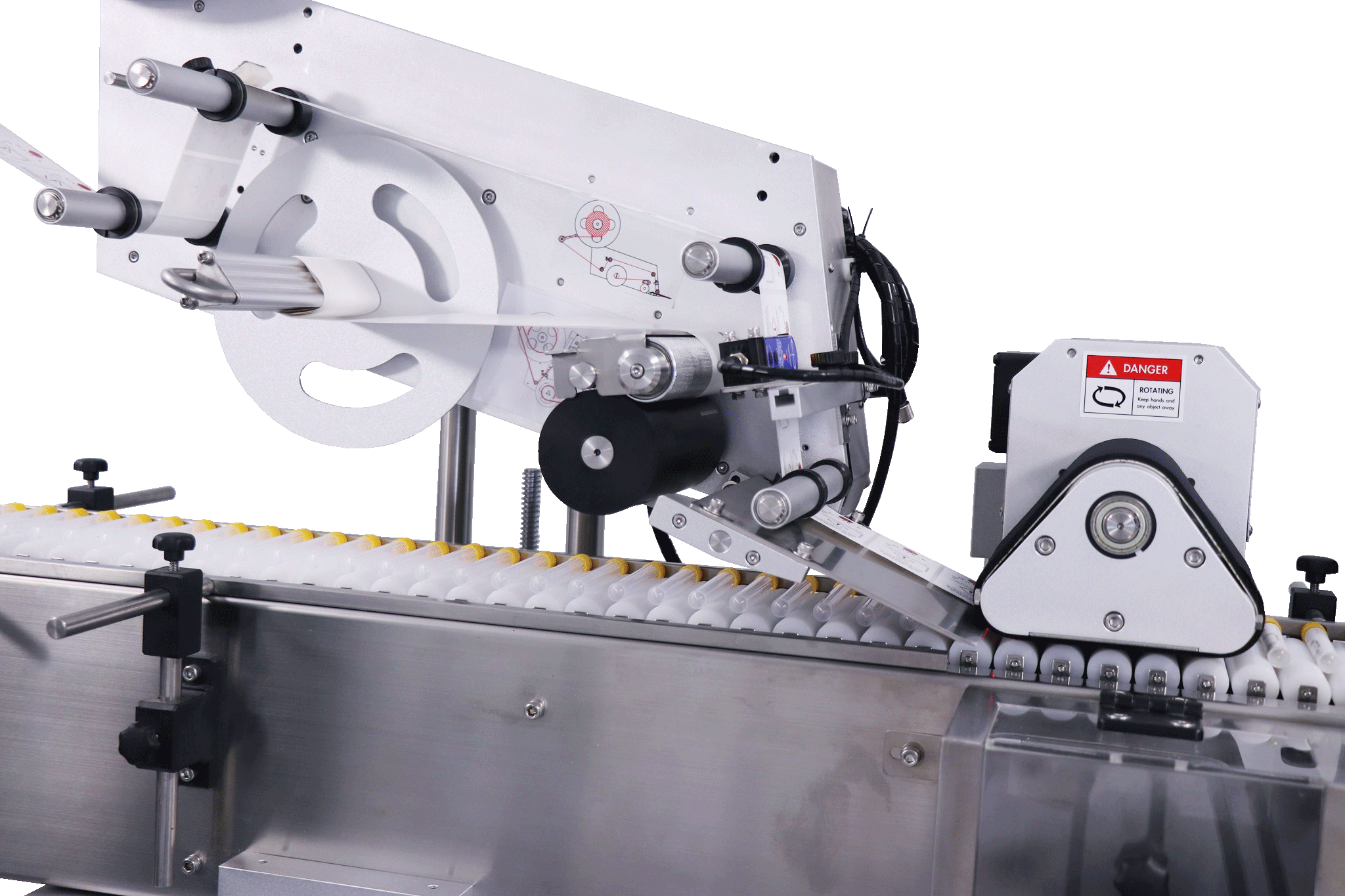

Fully Automatic Labeling Machines

Fully

automatic labeling machines provide the highest efficiency, operating

without human intervention and are especially suitable for large

production volumes. They are perfect for industrial labeling of bottles,

cans, and other round containers, ensuring rapid and precise label

application and easy integration into existing production lines.

The

LAB8050 labeler is an excellent example for small productions. These

machines can be equipped with additional modules to meet specific

requirements, such as a thermal printer for printing expiration dates.

Fully automatic labeling machines are the top choice for large companies reliant on efficiency and high production numbers.

Applications of Bottle Labeling Machines

Bottle

labeling machines are used across various industries to ensure precise

and efficient labeling. In the beverage industry, bottle labeling is

crucial for consistent brand presentation. Here are some key application

areas:

Beverage Industry:

These

machines are essential for labeling bottles of beer, wine, water and

soft drinks. They ensure seamless application of labels on various

bottle sizes and shapes, providing a consistent brand presentation.

Proper labeling enhances brand perception and consumer trust.

Food Industry:

Bottle labeling

machines are frequently used for labeling jars and bottles of products

like jams, honey, sauces, and other packaged goods. They provide and

efficient solution for product labeling and branding. Clear and readable

labels are crucial for providing consumers with necessary information,

and labeling machines ensure correct and complete label application.Cosmetics and Pharmaceutical Industry:

In

these sectors, labeling machines ensure correct labeling of products

such as shampoos, lotions, perfumes, medical products, and supplements.

They ensure compliance with legal regulations and enhance the aesthetic

appeal of packaging. Accurate label placement is essential for clear

product information and preventing confusion. In the pharmaceutical

industry, precise labels are vital for safety and correct use.

Bottle

labeling machines offer a versatile solution for accurate and appealing

label application. They are essential for businesses that prioritize

high-quality packaging and product labeling. Whether labeling everyday

consumer goods or specialized products, these machines provide the

necessary precision and flexibility.

Buying Guide for Bottle Labeling Machines

Key Factors to Consider When Choosing a Bottle Labeling Machine

When

purchasing a bottle labeling machine, consider factors such as label

size and type, desired production speed, and budget. It is advisable to

read reviews and comparisons to find the best machine for your specific

needs. Additional considerations include compatibility with existing

production lines, ease of maintenance, and manufacturer support. Some

machines offer additional features such as variable data printing, which

is particularly relevant for the pharmaceutical and food industries.

Another

important aspect is the machine's adaptability to different bottle

types and sizes. Ensure that the labeling machine is flexible enough to

handle various products, especially if your product range changes

frequently. Investing in a high-quality machine can save costs in the

long run by reducing downtime and maintenance expenses.

If

you need guidance, do not hesitate to contact us. Our expert team will

help you find the right solution and guide you through the selection

process to ensure your requirements are met. We also offer training to

ensure your staff can operate the machines efficiently and safely.